Service

- Home

- Service

01

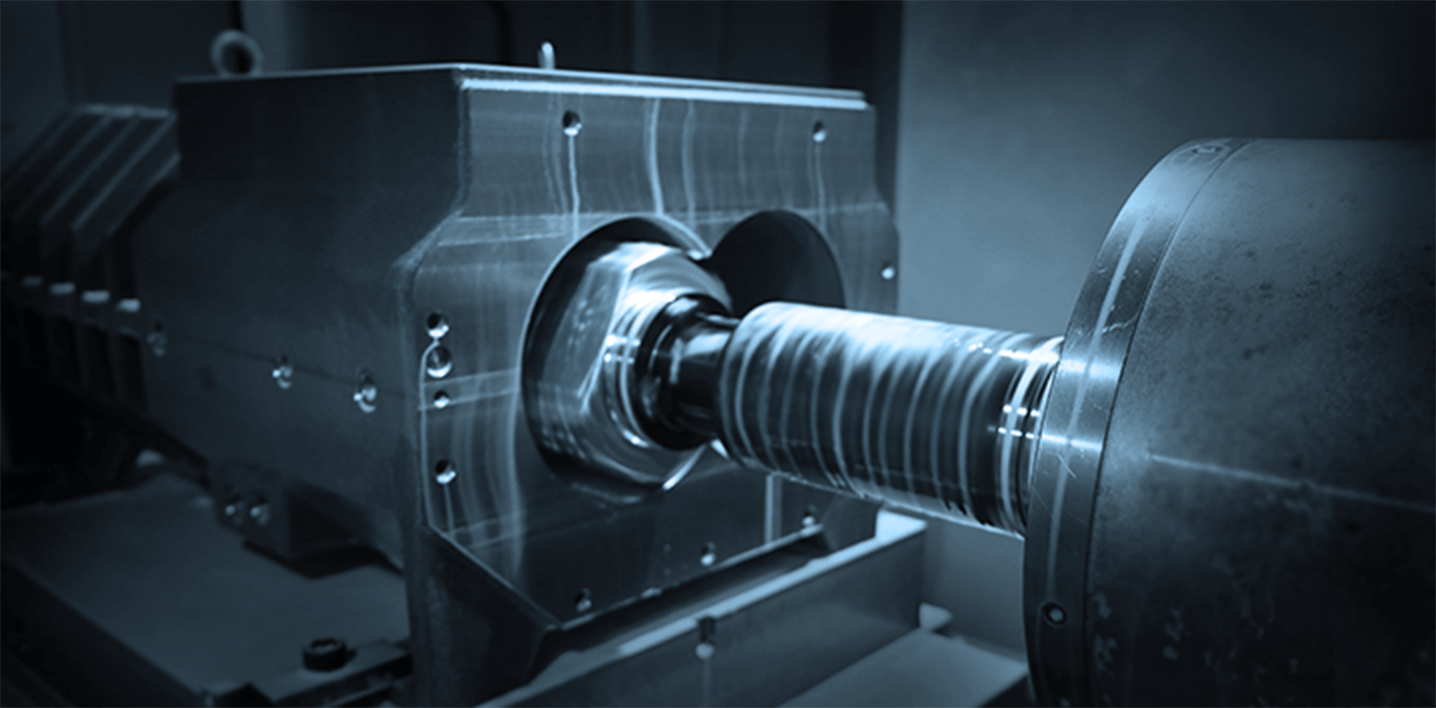

CNC Manufacture

Using CNC machines, we turn design drawings into programs that precisely control cutting tool moving profile, producing high-precision, uniform parts. Besides that, a well-designed fixture is also crucial to this process, and Howway’s expertise in fixture design ensures the most efficient , stabilized and economic production solutions.

02

CMM Measuring

CMM (Coordinate Measuring Machine) technology uses reliable equipment and fixtures to precisely measure object dimensions and shapes. Beyond verifying machining quality, it digitizes production data to help optimize processes. This service is widely applied in manufacturing, mechanical engineering, and product R&D.

03

CNC Tool Production

Cutting tools are crucial for CNC machining, made from high-quality carbide for milling, drilling, and engraving. Howway specializes in developing CNC cutting tools like boring heads, tool holders, and tapping tools. By producing and controlling quality in-house, we ensure reliable tool performance.

04

CAD CAM

Integrated Service

Integrated Service

The mechanical design and machining integration service provides comprehensive support from concept to production, including design, analysis, material selection, prototype fabrication, and manufacturing. This service streamlines the entire process, saving time and costs. As a one-stop solution, it ensures product quality, efficiency, and timely delivery.

05

Mechanical Assembly Service

In addition to metal part machining, Howway also offers mechanical assembly services, focusing on assembling various mechanical parts and components into complete products. This service covers the entire process, from part inspection to final testing and calibration.