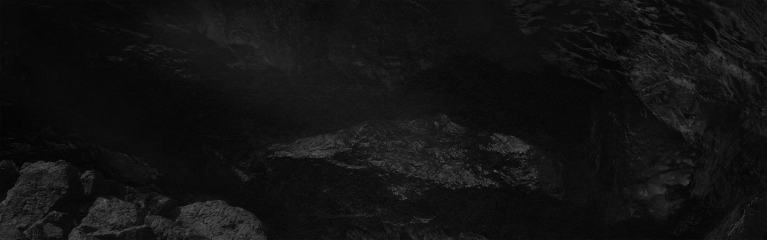

High Torque Precision Tool Holder (90 Degree)

Material:A7075 (Cut from Solid Material)

Dimension:200 x 165 x 155(mm)

Geometry accuracy requirement :

Φ80 +/-0.005、Φ42 +/-0.005、Φ121.5 +0.005 ~ +0.015

○: 0.005 ◎:0.01 ⌯: 0.015

//: 0.01 ⊥: 0.01 ⏥: 0.01

Dimension:200 x 165 x 155(mm)

Geometry accuracy requirement :

Φ80 +/-0.005、Φ42 +/-0.005、Φ121.5 +0.005 ~ +0.015

○: 0.005 ◎:0.01 ⌯: 0.015

//: 0.01 ⊥: 0.01 ⏥: 0.01

Application:CNC Milling Center

Manufacture Equipment : Mazak HCN-6800

CAM Software:Siemens NX CAM + Mazatrol CAM

Inspect Equipment:Zeiss Accura CMM 122410

Manufacture Equipment : Mazak HCN-6800

CAM Software:Siemens NX CAM + Mazatrol CAM

Inspect Equipment:Zeiss Accura CMM 122410

Feature

CNC precision tool holders require not only spindle direction accuracy but also geometric precision in all six spatial orientations. In high-speed applications, perfect alignment with the machine interface is critical, as even minor errors can cause heat, noise, and tool damage, compromising performance. Enhancing precision in manufacturing improves efficiency and reduces wear on surrounding components.

Howway Precision Tech. uses Zeiss CMM to inspect the geometric accuracy of all boring holes’ location, ensuring smooth gear meshing and precise tool holder dimensions. This data-driven approach helps optimize tool usage and production parameters for maximum efficiency.